Phoenix Filtration features the Straight Line brand of vacuum filtration systems. Each system is made of a grade of stainless steel with AWS certified weldments. Highly experienced personnel are part of the technical process to provide the best system to meet the application. Straight Line Vacuum Systems start with a base package and then are custom built for each application requirement. The systems are extremely robust and experience little wear during the course of operation.

The Straight Line Filter originated from the need for a practical horizontal vacuum filter with a separable filter medium which would overcome the mechanical and physical problems (such as blinding and discharge difficulties) inherent in horizontal pan type filters. The Straight Line Filter concept was born in 1957 and evolved rapidly from impractical, bolted grid plates to the present continuous belt concept in 1961 when the first Straight Line Filter was introduced.

Since its introduction by Straight Line Filters, Inc., continuous belt filtration has become the method of choice in many industries. Customers of Straight Line Filters, Inc. maintain direct contact with our management assuring individual and professional service from inquiry through testing, purchase, construction, start-up and in plant operation.

Because laboratory vacuum filtration is commonly done with Buchner funnels, Straight Line Filters, Inc. has adopted the concept of the Buchner Funnel in its design for continuous filtration. This concept has been so successfully adopted that the correlation between Buchner Laboratory Tests and Straight Line Filter operations allows us to perform sizing and cycle studies with a modified Buchner Funnel. Many customers use this tool to continuously monitor their filtration process.

Straight Line Continuous Vacuum Filter

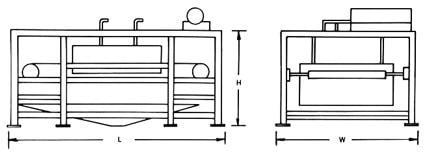

Listed below are our standard production model filters. Optional materials of construction include 304 S. S., 316 S.S. And elastomer coated. Drainage belts are available in various elastomers to suit process conditions. Vacuum box compartment design is in accordance with process requirements. Dimensions given below: (H) height — to the top of frame, not including drive; (L) length —shown exclusive of discharge device; (W) width includes chain guard; weights are typical for carbon steel construction. Areas shown in table are active filtration areas. Do not arbitrarily compare area requirements with other filtration systems. Filtration rates are generally higher on a Straight Line Filter.

| Model | Laboratory | 1 x 3 (Pilot) | 2 x 3 | 2 x 5 | 2 x 7 | 2 x 9 | 2 x 11 | 2 x 13 | 2 x 15 | 4 x 9 | 4 x 11 | 4 x 13 | 4 x 15 | 4 x 20 | 4 x 25 | 4 x 30 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Active Area (Sq. Ft) | 0.5 | 2.0 | 4.5 | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 31.5 | 38.5 | 45.5 | 52.5 | 70.0 | 87.5 | 105.0 |

| Drive (H.P.) | 1/8 | 1/4 | 1/2 | 3/4 | 1.0 | 1.5 | 2.0 | 3.0 | 3.0 | 3.0 | 5.0 | 5.0 | 5.0 | 7.5 | 7.5 | 10.0 |

| Length | 34" | 5' - 11" | 8' - 0" | 10' - 0" | 12' - 0" | 15' - 0" | 17' - 0" | 19' - 0" | 21' - 0" | 15' - 0" | 17' - 0" | 19' - 0" | 21' - 0" | 26' - 0" | 31' - 8" | 37' - 3" |

| Width (Inches) | 15 | 24 | 36 | 36 | 36 | 36 | 36 | 36 | 36 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Height (Inches) | 15 | 74 | 52 | 52 | 52 | 52 | 52 | 52 | 52 | 52 | 52 | 52 | 52 | 54 | 62 | 68 |

| Weight (Pounds) | 375 | 1500 | 1375 | 1510 | 1810 | 1135 | 2430 | 2675 | 2950 | 2950 | 3200 | 3550 | 3775 | 5400 | 6350 | 7250 |

Filtration Design and Evaluation

The choice of proper combination of filter area, filter cloth and cycle time, for the most efficient filtration of a product, is accurately determined using the three-step method pioneered by Straight Line Filters, Inc.

Step 1 — Laboratory Study

A small, representative sample is all that is necessary for this preliminary step. With this sample and pertinent information about your requirements for filtrate and cake recovery, we develop the essential parameters needed to design a filter for your process. Tests are done in our laboratory on a modified Buchner Funnel. These test kits are available from Straight Line Filters, Inc.

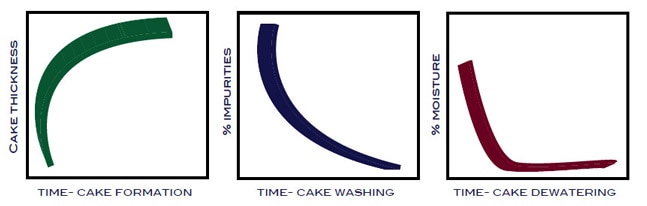

Our Buchner Test develops information relating to the controlling factors: times for cake formation, washing and dewatering, Curves, such as those shown here, are developed for theses functions. Knowledgeable interpretation of these curves and their relation to process requirement, allows us to determine the individual cycle times and to recommend equipment sizing.

Cake and filtrate samples together with a detailed test report are submitted along with equipment recommendations. Special laboratory procedures using the Buchner Funnel have been developed to evaluate other process operations such as countercurrent washing, leaching and chemical treatment.

Step 2 — Pilot Plant Study

A complete filtration system available with feed and level controls and other auxiliaries necessary for demonstration of the capabilities of the Straight Line Filter system. Pilot study normally is suggested in order to confirm rate data on a continuous basis and to familiarize a potential customer with the operation and simplicity of this equipment.

Step 3 — Rental Program

Straight Line Filters, Inc. Rental equipment provides an economical method of in plant verification of test results under production conditions, development of plant operating procedure, production of product for further evaluation and determination of final design. Our Standard Rental Machine is the package 1×3 Model. 4. Data obtained by operating this filter are directly scaleable to production size equipment.

System Setup

Phoenix Filtration works with you to provide installation of Vacuum Filtration Systems. Customers can do the installation and Phoenix Filtration will travel on-site to check the equipment and conduct the start-up and commissioning. Also, operation and maintenance training is provided to the operators to ensure safety the process is running smoothly.

System Overview

The filtration system features a PLC control panel which can be networked together to run multiple operations. There is variable control right at the filter which is continuously moving, the system incorporates properly sized drives and motors run by a VFD system. Safety equipment is also in-place including an enclosed filter mesh and safety pull chain to stop the system.

Test Systems

Phoenix Filtration offers on-site test systems to ensure that the equipment provides the correct filtration specifications. A lab unit is sent to the site as a rental with an option to purchase. This is a 6” machine to accommodate most any application and is a modified funnel to check cake thickness and moisture content where there are many different solids or liquids in the application.

Applications:

- Solid liquid separation

- Wash mother liquor out

- Dewatering